ACTIVATION OF BLENDED CEMENT BY AMINE ADDITIVES

In order to reduce CO2 emissions coming from cement production, manufacturers are increasingly making use of supplementary cementitious materials (SCMs). However, the use of SCMs such as slag, fly ash or limestone usually leads to a decrease of cement strength performances, especially at early age. The addition of an efficient activator can allow to compensate this loss of performances. Different molecules and salts can be used in the formulation of additives. We are discussing here about the influence of alkanolamines on cement reactivity.

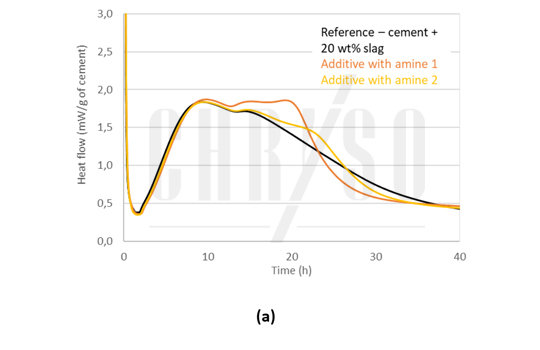

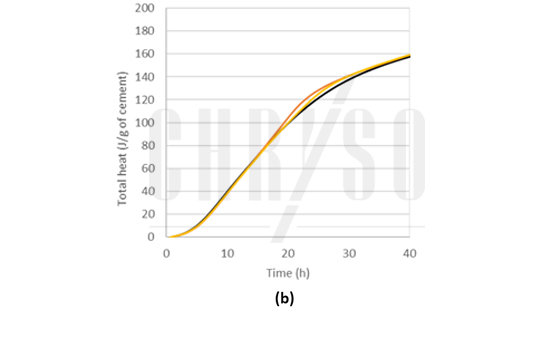

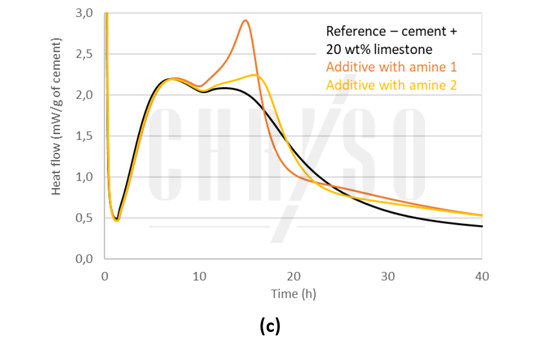

Indeed, alkanolamines are known to activate cement hydration especially at long term (more than 7 days), but they can also have an impact during the first days of hydration. By following the evolution of heat flow and cumulated heat with an isothermal calorimeter, it is possible to evaluate the influence of different amine-based additives on hydration kinetics.

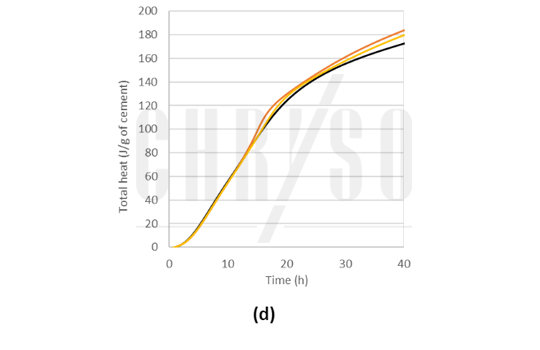

Additives prepared with the same raw materials and 2 different amines (amine 1 and amine 2) were formulated and added to blended cements containing 20 wt% slag or 20 wt% limestone. According to Figure 1(a and c), both additives allow to increase the heat flow liberation during hydration of blended cements, which can be attributed to favored calcium aluminate hydration. The heat cumulated over 40 hours of hydration in the cement with limestone (Figure 1d) also rises in presence of amine additives. Moreover, amine 1 allows to increase more significantly the intensity of the hydration peak and the cumulated heat than amine 2. This amine might consequently be a more efficient early age activator.

Figure 1 : Heat flow evolution and cumulated of a cement blended with 20 wt% slag (a,b) and 20 wt% limestone (c,d) in presence of amine-based additives

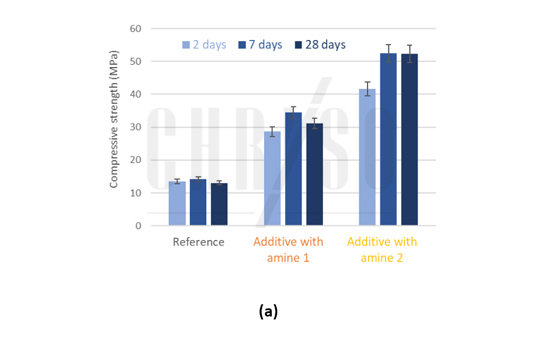

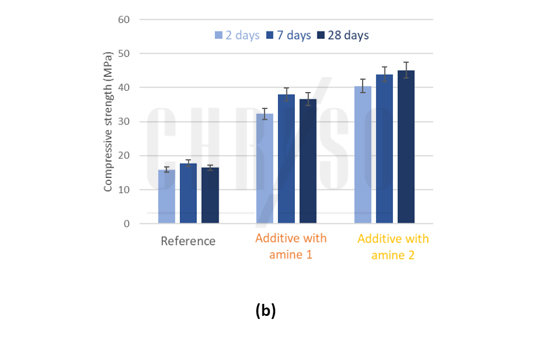

Regarding mechanical performances (Figure 2), the presence of amine 1 in the additive allows to improve both the early and long-term compressive strength (2, 7 and 28 days) in the two blended cements compared to the reference. Amine 2 only allows a slight strength gain at 7 days and a stronger gain at 28 days. Thus, depending on the nature of the amine used in the additive, it is possible to modulate the mechanical performances of the cement.

Figure 2 : Compressive strength at 2, 7 and 28 days of a cement blended with 20 wt% slag (a) and 20 wt% limestone (b) in presence of amine-based additives

As blended cements are usually slowly reactive at early age of hydration, amine 1 appears to be a very efficient molecule to compensate hydration retardation. The use of this amine in a formulation also still allows to maintain high mechanical strength gain at 28 days. This knowledge about amines allowed the R&D teams at CHRYSO to develop tailor-made additives for blended cements, leading to the CHRYSO®AMA 100 EL Technology.

Marie JACHIET – PhD in Chemistry and Physico-Chemistry of Materials