THIXOTROPY AND FILL-FREE® ADMIXTURES

Cement pastes are thixotropic; left at rest, their rheological constants —among which viscosity— increase over time. Under steady shear, cement paste viscosity decreases (which qualifies it as shear-thinning) but may take some time to reach a steady value (which qualifies it as thixotropic). Flow steadiness is highly useful in most concrete operations; as will be shown here, it is sometimes hindered by thixotropy but fortunately, polycarboxylate ether (PCE) technologies may help mitigate its effects.

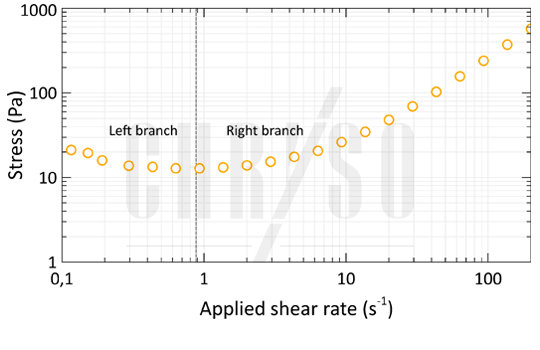

Rheometers may be set to record flow curve measurements only after steady flow is reached. When plotted on a linear scale, such curves have the usual shape of stress smoothly decreasing towards a finite yield stress when shear rate decreases. On a double-log scale however (Figure 1), the flow curve features a U-shape, with stress increasing again when shear rate vanishes. This is very uncommon and deserved a closer look.

Figure 1 – Flow curve featuring the effect of thixotropy

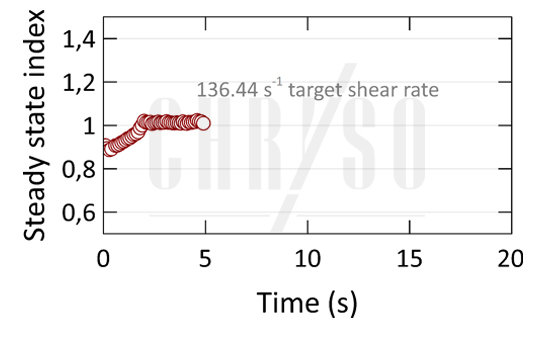

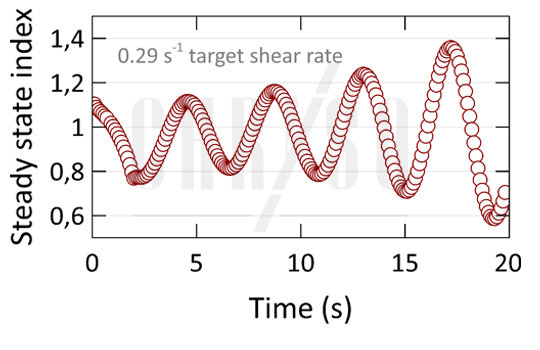

The right branch of the curve is composed of data points for which steady state was achieved in a couple of seconds. The data recorded in the left branch, on the contrary, never reached any steady state and instead oscillated between two values, showing that the structural build-up of the paste competes with shear and prevents homogeneous flow.

Figure 2 – Steady state reaching times for two data points on the right flow branch (a) and on the left flow branch (b)

The minimum point on the curve thus defines a frontier between two flow regimes: homogeneous and steady flow at high shear rate, thixotropy-influenced and heterogeneous flow at low shear rates. This was already observed by other researchers[1]–[5].

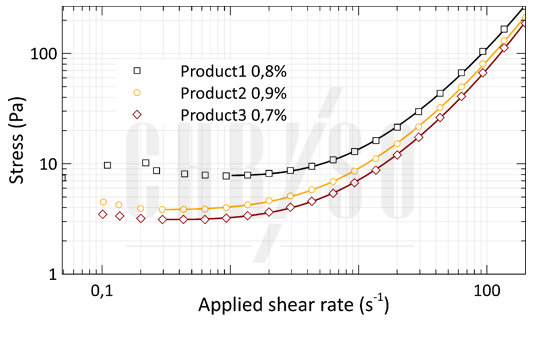

This critical point may be used as a thixotropy indicator: the further down in shear rate and stress, the milder the thixotropy. The further up in rate and stress, the more intense the thixotropy. Our R&D teams have learned to compare PCE superplasticizers according to their ability to ‘move’ the critical point on flow curves of cement pastes having a close workability. From this study, a whole range of formulations able to attenuate thixotropy was developed. Concrete scale tests were designed to confirm the rheometer-scale observations, like channel filling time and level. Very soon after, the ‘Fill-free®’ phrase was coined to describe this new family of products.

Figure 3 – Flow curves of three superplasticizers with dosages set for similar workability. Products 2 and 3 are part of the Fill-free® family

Pascal BOUSTINGORRY – PhD in construction materials

References

[1] N. Roussel, “A thixotropy model for fresh fluid concretes: theory, validation and applications,” Cem. Concr. Res., vol. 36, no. 10, pp. 1797–1806, 2006.

[2] N. Roussel, R. Le Roy, and P. Coussot, “Thixotropy modelling at local and macroscopic scales,” J. Nonnewton. Fluid Mech., vol. 117, no. 2–3, pp. 85–95, 2004.

[3] G. Picard, A. Ajdari, L. Bocquet, and F. Lequeux, “Simple model for heterogeneous flows of yield stress fluids,” Phys. Rev. E, vol. 66, no. 5, p. 051501, 2002.

[4] G. Picard, A. Ajdari, F. Lequeux, and L. Bocquet, “Elastic consequences of a single plastic event: A step towards the microscopic modeling of the flow of yield stress fluids,” Eur. Phys. J. E, vol. 15, no. 4, pp. 371–381, Dec. 2004.

[5] G. Picard, A. Ajdari, F. Lequeux, and L. Bocquet, “Slow flows of yield stress fluids: Complex spatiotemporal behavior within a simple elastoplastic model,” Phys. Rev. E – Stat. Nonlinear, Soft Matter Phys., vol. 71, no. 1, p. 010501, 2005.