Compatibility between calcined clay-blended cements and PCE superplasticizers

Introduction

The LC³ project has shown how the use of calcined clay for partially substituting Portland clinker allows reducing the carbon footprint of concrete while maintaining most of its properties in the hardened state. However, it is less clear how much the source of clay, and more importantly its mineral and physical characteristics, influences the efficiency of superplasticizers in bringing an acceptable rheological behaviour.

Calcined clay characteristics

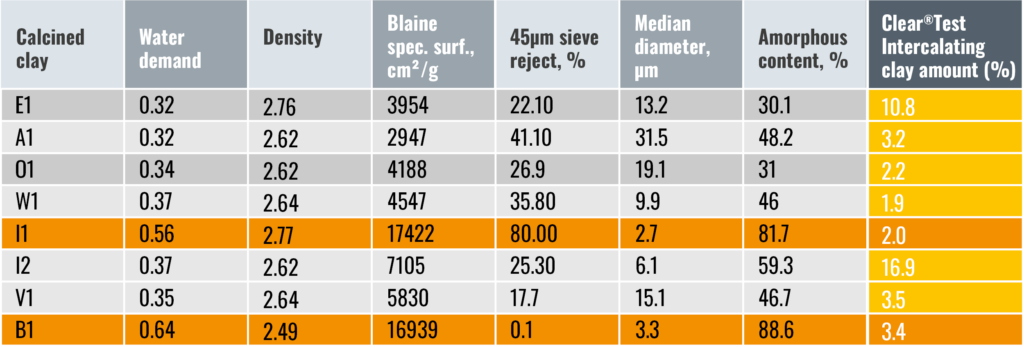

The results obtained through a series of different methodologies are summarized in Table 1. The samples chosen feature a very broad range of characteristics. It is particularly obvious for the Blaine specific surface ranging from 3000 to 17500 cm²/g and the amorphous content ranging from 31 to 89%. On several cases, the water demand was quite low, in the 0.30-0.35 range.

Surprisingly, despite calcination, all clay samples feature some PCE intercalation characteristics, which for a couple of them amounts up to 10-17% of equivalent sodium montmorillonite, as assessed by our proprietary Clear®Test.

Rheological results

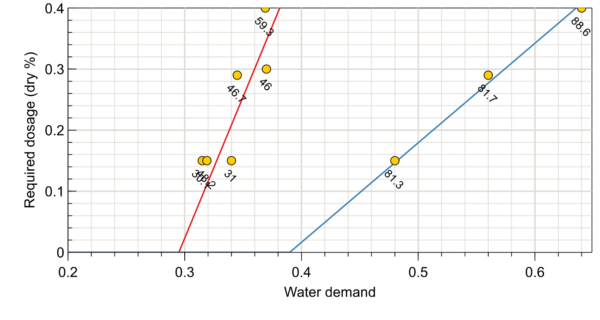

The study was carried out by increasing the dosage until reaching a yield stress in the range of 0.5-1.5 Pa. The required dry polymer dosages finally appear to range between 0.15 and 0.45% depending on the clay source (Figure 1). It seems to increase with water demand and amorphous content, with the purest clays a.k.a. metakaolins, having their own correlation (right of the graph).

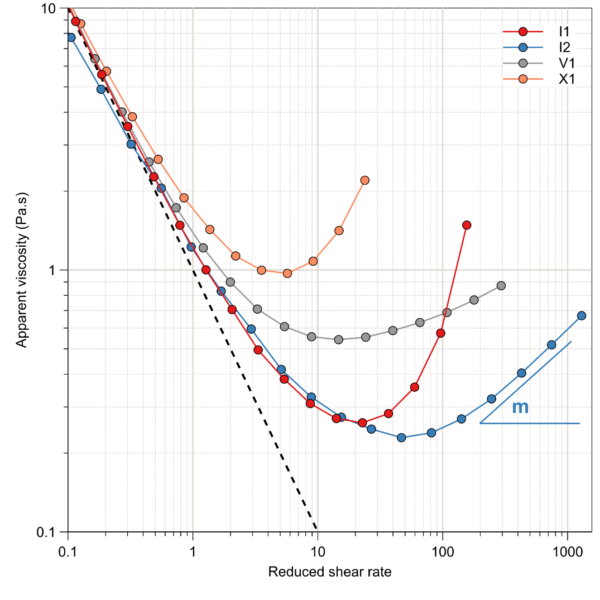

More surprisingly, shear-thickening branches are observed at high shear rate with a broad range of intensities (graph below). This feature is believed to have detrimental effects on concrete pumping efficiency and must be considered when selecting a calcined clay.

Correlation with calcined clay characteristics

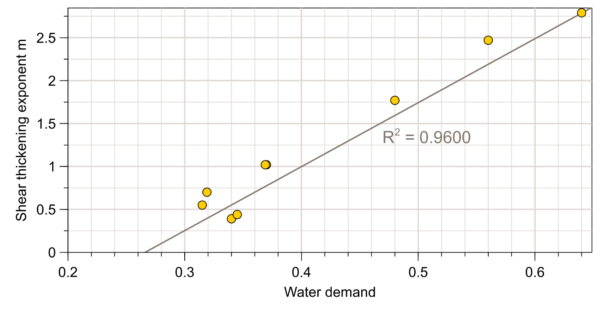

The required dosage to obtain target yield stress seems to be dependent upon a couple of clay characteristics, namely its ability to intercalate PCE and specific surface. As shown in the figure below, a good correlation was obtained between the slope of the shear-thickening branch and water demand. We expect this correlation to stem from a very strong influence of the maximum packing fraction, approached by the water demand measurement, on shear-thickening [3,4].

Conclusion

Beyond their different responses to PCE superplasticizers, a striking feature of the obtained suspensions is the presence of shear-thickening branches which strongly depend on the clay source.

Among the multiple characteristics studied, it seems the most relevant are specific surface, water demand and PCE intercalation properties. It is advised here that such properties should be carefully assessed before selecting any unknown source of calcined clay.

Pascal BOUSTINGORRY – PhD in construction materials

Keywords:

shear-thickening, thixotropy, PCE intercalation, calcined clay

References

[1] N. Roussel, R. Le Roy, P. Coussot, Thixotropy modelling at local and macroscopic scales, J. Nonnewton. Fluid Mech. 117 (2004) 85–95. https://doi.org/10.1016/j.jnnfm.2004.01.001.

[2] M. Wyart, M.E. Cates, Discontinuous shear thickening without inertia in dense non-brownian suspensions, Phys. Rev. Lett. 112 (2014) 1–5. https://doi.org/10.1103/PhysRevLett.112.098302.

[3] R. Mari, R. Seto, J.F. Morris, M.M. Denn, Shear thickening, frictionless and frictional rheologies in non-Brownian suspensions, J. Rheol. (N. Y. N. Y). 58 (2014) 1693–1724. https://doi.org/10.1122/1.4890747.

[4] R. Mari, R. Seto, J.F. Morris, M.M. Denn, Shear thickening, frictionless and frictional rheologies in non-Brownian suspensions, J. Rheol. 58 (2014) 1693–1724. http://scitation.aip.org/content/sor/journal/jor2/58/6/10.1122/1.4890747 (accessed October 1, 2014).